An Interview with Spartan Controls

An energy management information system (EMIS) is one of the four activities in ERA’s Strategic Energy Management for Industry program. But what is an EMIS, and how can it help your industrial or manufacturing facility?

Spartan Controls is an EMIS vendor and Western Canada’s leader in industrial automation solutions. We spoke with Ian Ignatiuk, Solutions Consultant at Spartan, about the benefits of EMIS for Alberta facilities.

Ian, can you start us off by explaining “What is an EMIS?”

Absolutely. At Spartan Controls, our energy management information system is a software platform that uses sensors to track, analyze, and predict energy data across equipment based on current facility operating conditions. It provides visibility into the energy consumption of your facility and the places where overconsumption is occurring.

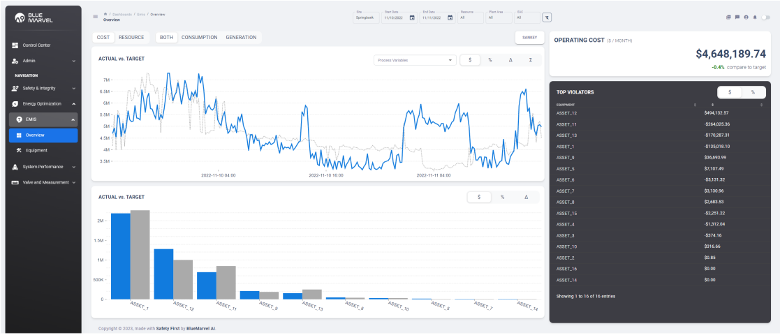

An EMIS looks like a dashboard, where you can see live energy usage and the top energy violators in your operations, but visualization is only one part of an EMIS. Data analysis, energy target-setting, notifications of overconsumption and where the overconsumption is occurring are all features of the platform. It’s an incredibly valuable tool. It helps industrial facilities reduce costs, cut emissions, and optimize performance.

Why is an EMIS important for industrial or manufacturing facilities?

Managing your energy without an EMIS is like trying to get somewhere in a city you’ve never been to without Google Maps. It will take you longer than you want, you’ll miss all the shortcuts, and you may never know how much time there is left in your journey.

An EMIS allows you to capture, quantify, and act on your energy consumption so you can adjust in real-time and reach your desired destination. It helps you save money, reduce greenhouse gas emissions, and run your operations more efficiently. We like to say it turns a large variable cost into a controllable expense.

Can you give us an example of EMIS in action?

I’ll give you a real-time scenario. A few years ago, one of our clients was conducting a large turnaround at their industrial facility. During the turnaround, there was a work order done that caused the plant’s steam generation measurement to appear lower than the true steam generation value. When the equipment started back up, it automatically cranked the fuel gas to generate more steam to match the steam target, using up valuable energy.

The EMIS signalled that fuel gas consumption was higher than expected for the steam target. After being notified by the EMIS, our client set the controls back to normal. They did some quick homework and found that the source of the problem was the work order. The issue was caught by the EMIS and fixed between 12-18 hours, before the facility went days without noticing the flaw in their operations.

Can an EMIS report on the energy usage of specific equipment?

Yes, definitely. At Spartan, we call groups of equipment “energy account centres.” An account centre can be all the lighting across your facility, the air conditioning units, the steam consumers or any collection of similar equipment. After adding sensors and measurements, and associated energy models to this group, you can report on its energy usage. If it’s a lighting system, an EMIS allows you to track lighting across your entire plant. If it’s a heating or cooling system, same thing.

What advice would you give to companies starting out with an EMIS?

I would say, “Think big, start small.” Focus on one process area in your facility with the best data infrastructure, then move on to collect energy information from other places. An EMIS is a powerful tool to help you save costs and reduce energy… take full advantage of it.